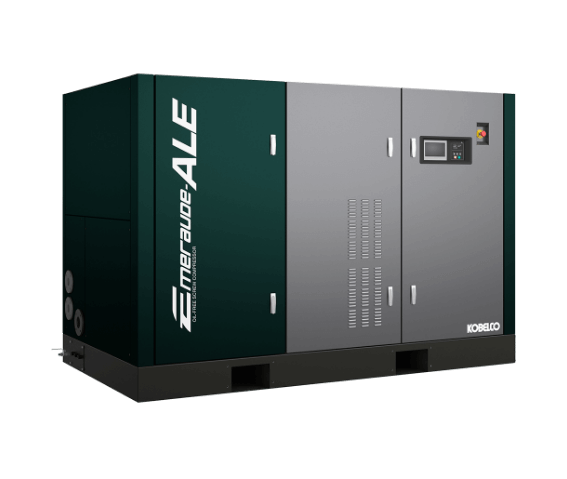

Ultimate Efficient Inverter Model

PT KOBELINDO COMPRESSORS

What makes it KOBELCO "Monozukuri"

“Monozukuri” literally means Production or Manufacturing in Japanese word. But this “Monozukuri” especially has meaning of integration of prowess, know-how, and spirit of Japanese manufacturing, which include sincere mind, pride for the quality backed by skill, dedication and the pursuit of innovation and perfection. Our endeavor for future technology, top quality, and for maximum customer satisfaction will not stop.